Improving Safety in the Construction Industry through Observability

Aswin Vijayakumar

Posted on January 5, 2023

Introduction

Observability in the Construction Industry is a new technique to improve the Productivity. In a Construction Site, especially Foundations Site, there will be many machines operating over a period of duration. The Construction Scheduling separates the Activities Recognized from Frames into a Project Gantt Chart. Such a Project Gantt Chart is integrated into BIM 4D, with autonomy.

Improving Safety

Construction Site Safety depends on people working at the site, the Quality of Machines imported into the Site, Rules laid out by Construction Project Managers, and the Design or a BIM Model of the Project. Safe use of phones within the designated areas in the Site, an awareness of health and safety risks at work, reporting any risks in the site, Safe and efficient materials storage and so on. Materials Storage involves Flammable materials, Storage areas, Pedestrian Routes, Storage at height, Tidiness and Deliveries such as planning deliveries on site to keep the amount of material minimum on the site.

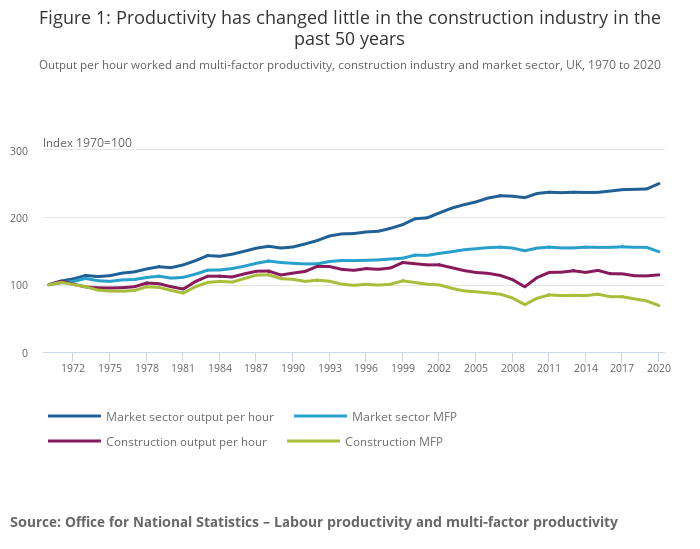

Productivity from 1972 onwards

From 1972 onwards, there is no improvement in the Multi-Factor Productivity in the Construction Sector. This indicates the energy, purchased services, land and facilities management. The greatest improvement is in the Market Sector output per hour. Market sector MFP and Construction output per hour are almost the same.

Observability by Parts

Observability by Parts is a method to selectively detect the Objects and Equipments, and recognize the activities to isolate a particular section of the work. By isolating a particular area of work, better safety can be introduced in the Site and working conditions because Enclosures can be sealed as well as governed using an Integrated Computer Vision platform.

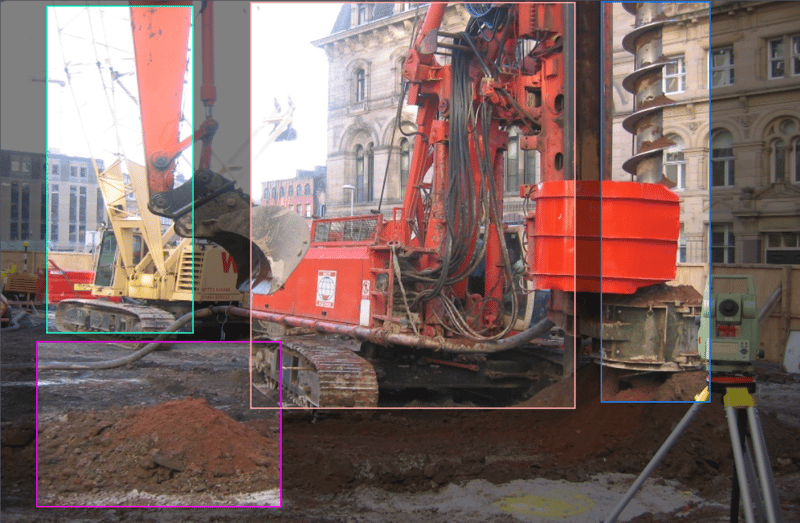

Full-view of the object detection frame using Computer Vision

By Detecting all objects, the objects and Equipments are recorded into the Software.

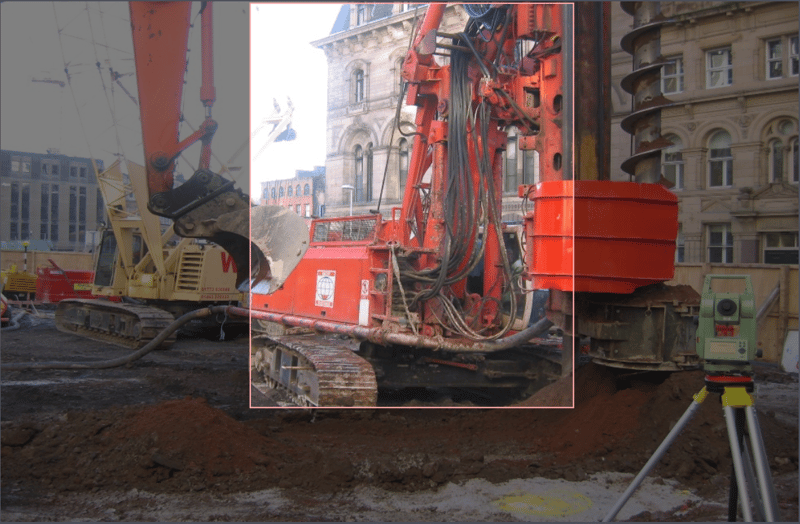

Partial-view of the object detection frame using Computer Vision

By Detecting some of the objects, only those objects which want to get exposed will be recorded into the Software.

Other Measures to Improve Safety

- Increases Safety due to Execution of Intermediary Activities

- More holistic identification and tracking of objects

Risk mitigation in the Construction Site through Observability

- Involving Costing while recognizing the Activities, and integrating with BIM 5D

- Efficiency and Risk reduction due to a Traceability on Material POs, Contract POs and Supplier POs

Conclusion

Integrating Observability for producing Construction Scheduling Gantt Chart, will require data collection of activities, and definition of well-defined Metrics.

Observability can be used for a Quality Inspection to generate Punch Lists in Construction Site for recording balancing works and deficiencies.

Another use of integrating Observability is to generate Daily Report which the Foreman or the Project Manager is responsible for

A Project Field Observation, involving the screenshots of deficiencies will be added by the project person

A Demand Inspection of the Construction site involving an activity list recognized and the deficiencies detected using Scheduled Walks

Thanks for reading the article

This is based off of a LinkedIn article:

https://www.linkedin.com/pulse/integrating-observability-construction-sector-aswin-vijayakumar/

Posted on January 5, 2023

Join Our Newsletter. No Spam, Only the good stuff.

Sign up to receive the latest update from our blog.